Injection moulded components and hybrid parts for a broad range of uses in electrical engineering, conveyors, measurement and control systems. Anything is possible.

Our customers place stringent demands on the longevity, chemical resistance and smoothness of our components – especially in this broad and diverse market segment. This we manage by choosing the right materials, ensuring the plastic-compatible design of all components and by meeting the toughest location, shape and position tolerances.

Our mission is to implement systems and manufacture components more efficiently than the competition. To do this, we put our efforts into adhering to our quality standards, stable processes, sensible automation solutions and the very latest injection moulding- and co-injection technologies.

Since 1937 we have carried out over 2,000 industrial projects with over 500 different materials.

It has taken us a lot of hard work over many decades to attain our status as a quality leader. Since the introduction of on-site thermoplastic and duroplastic processing, we have been working closely with granule manufacturers and our customers towards developing innovative, economical plastic products. We are always one step ahead.

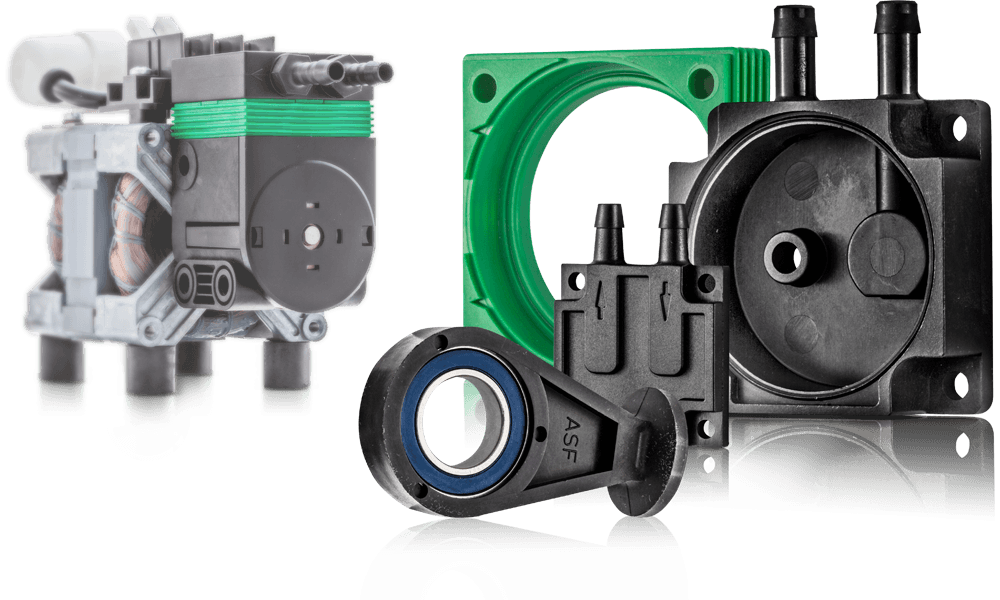

Pumps

Low-wear and chemical-resistance during the entire service life

From membrane to fluid pump. Our components and systems surpass global specifications for chemical and leak resistance. As well as meeting the required tolerances and use of low-wear plastics, we can achieve lasting quality, weight and cost advantages by using plastics as a substitute for metals.

- Pump console

- Head cover

- Valve cap

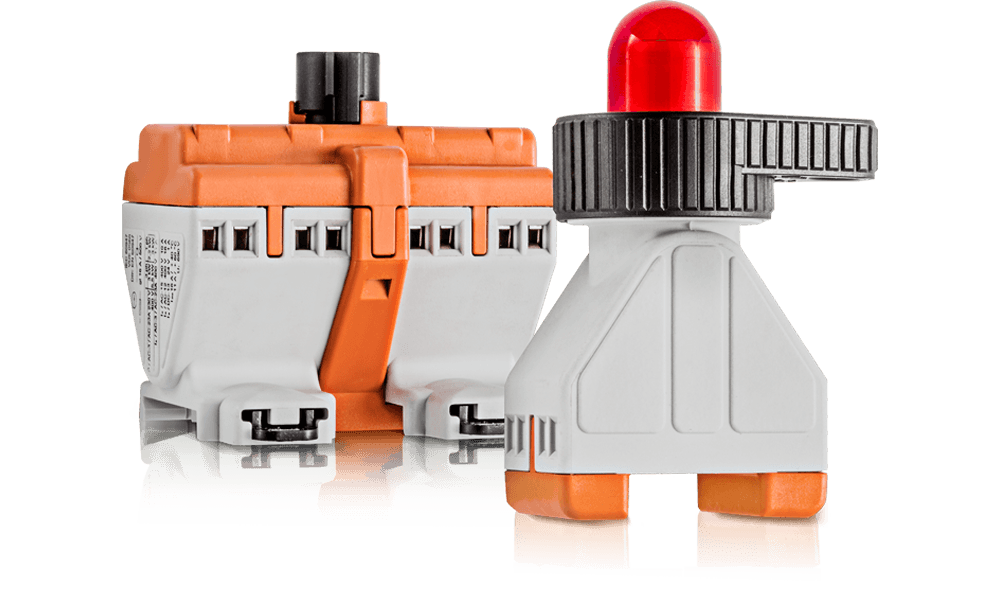

Electrical engineering

From goods transport to wind energy – ultra-precision and in size-restricted construction spaces

Our components prove their worth wherever large flows of energy are being converted. Due to the often highly-sensitive built-in electronics required here, there are particular specifications concerning evenness, cleanliness and the strictest position tolerances. At the same time, the high-performance plastics used must be of have especially high strength to withstand all of the forces continually acting upon them.

- Housing parts

- Covers

- Explosion-proof switches

- Connectors

- Load switches

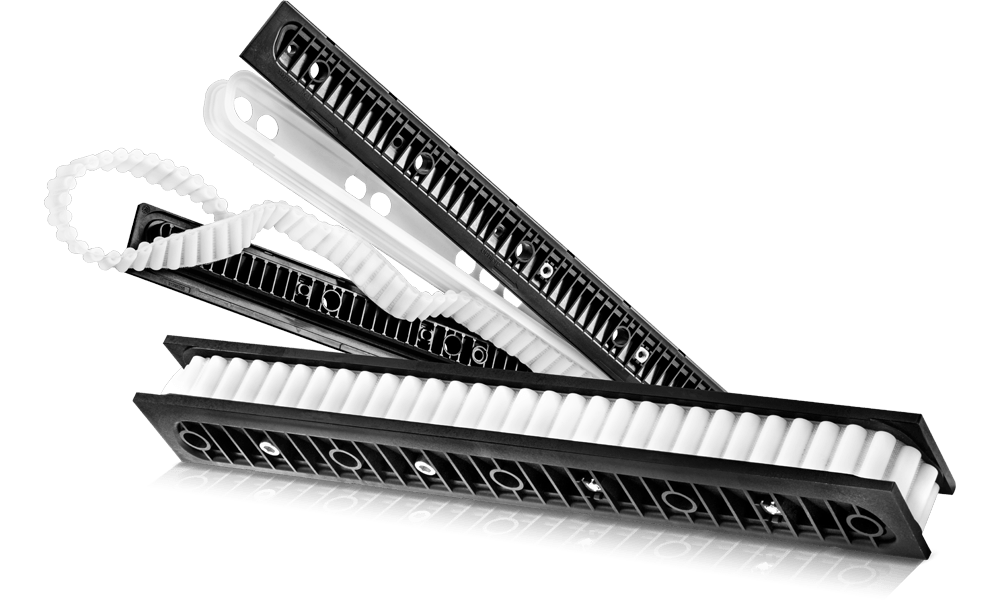

Conveyor technology

Tailor-made lightweight solutions for smoothly running conveyor operation

In the area of conveyor technology, our customers benefit from the excellent running properties of our high-performance plastics. Along with less wear, practically zero maintenance and minimising of roller noise.

- Covers

- Rollers

- Side panel

- Central unit

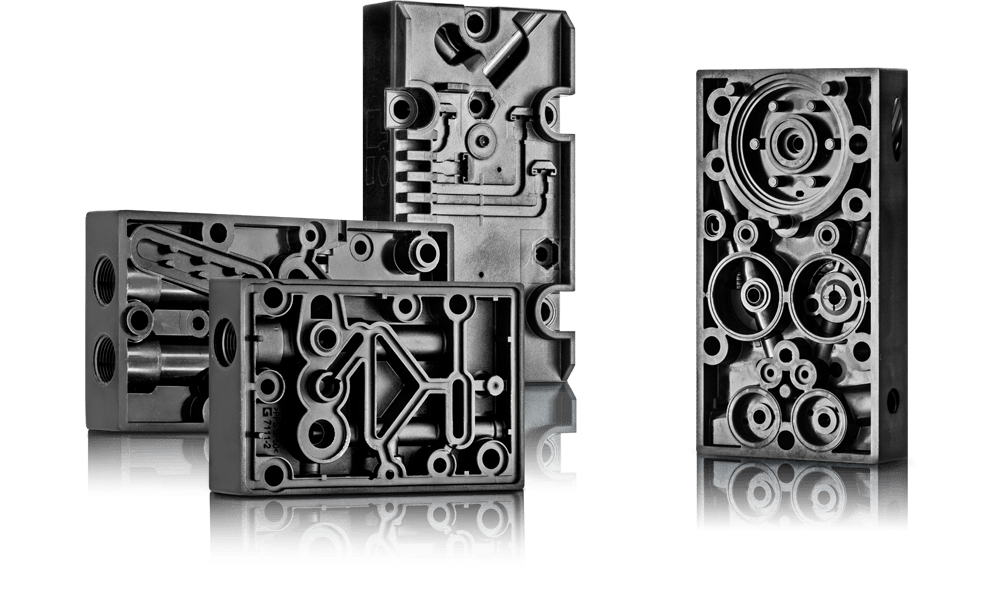

Control engineering

Functional, ultra-precise valve and cap solutions

Our valve components are used in electro-hydraulic valve actuators and electrically-controlled actuators (also in explosion proof areas). Due to high stiffness and temperature resistance requirements, we use PPS plastics here. High dimensional accuracy and finely drilled holes ensure precise functioning of controls. Our pot core caps are mostly used in inductive sensors. Particularly challenging has been achieving especially thin wall-thicknesses and round geometries in order to use the component in the fully-automated production process without disruption.

- Pill housing

- Throttle plate

- Valve enclosure

- Pot core caps

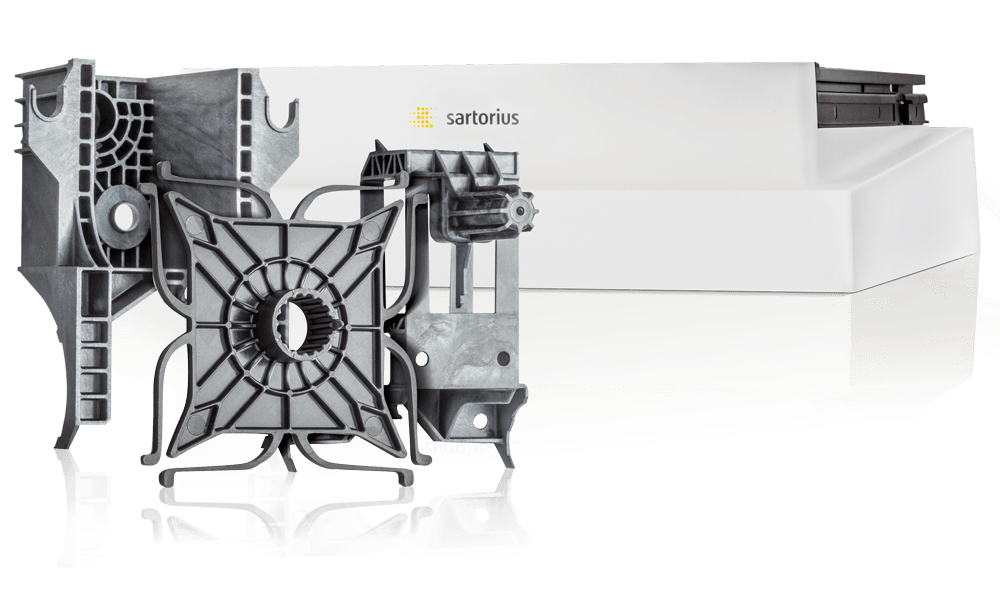

Measurement and weighing technology

Precision components for precise, reliable measurement results

Working in tandem with our customers we develop and manufacture plastic systems for surface measurement equipment, industrial and precision scales. Conductive plastics (LCP) come into extensive use. These are especially good at deflecting failing currents and static charge. One of our strengths in this area is the completion of components, e.g. by adhering guide rails and magnetic films.

- Lower casings

- Shell connections

- Cowls

- Housing for surface measurement devices

The following reference customers can attest to our performance going back many years. Including: